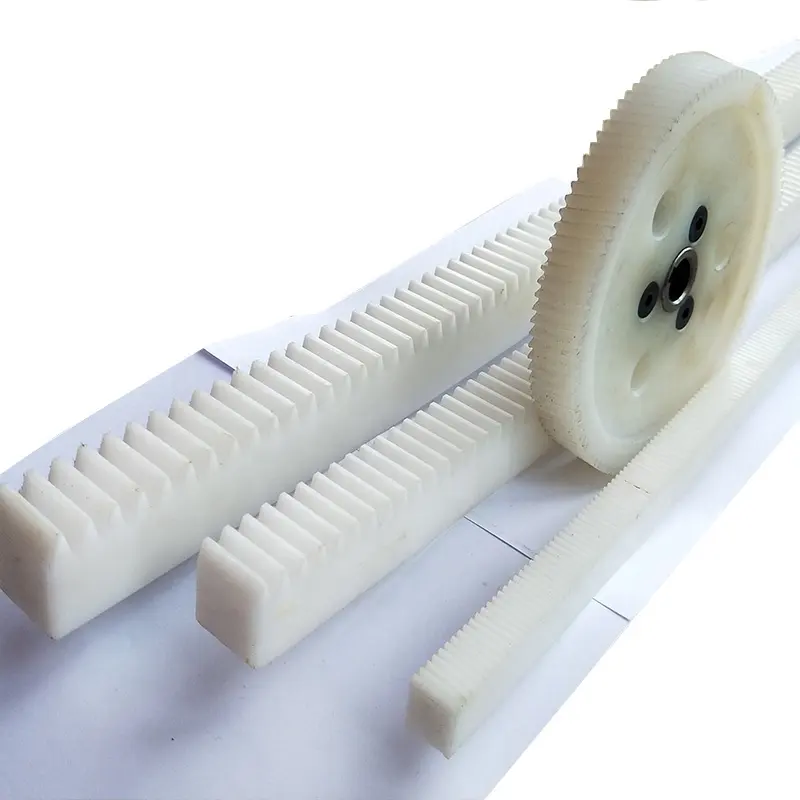

Product Description

Product Description

|

Products |

Gear |

|||

|

Module |

M0.3-M10 |

|||

|

Precision grade |

DIN5, DIN6, DIN7, DIN8, DIN10 |

|||

|

Pressure angle: |

14.5 degree, 15 degree, 20 degree |

|||

|

Material |

C45 steel, ,304SS, 316SS, 20CrMo,40Cr, brass, nylon, POM, and so on |

|||

|

Heat treatment |

Hardening and Tempering High Frequency Quenching Carburization etc |

|||

|

Surface treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|||

|

Application |

Precision cutting machines.Lathes machine |

|||

|

Machining process: |

CNC engine latheCNC milling machine |

|||

Detailed Photos

Test

Inspection steps before delivery: Use GO/Nogo inspect hole—Use micrometer check dimensions—Next use stiffness detection system inspect hardness–Finally use CMM inspect precision

Packaging & Shipping

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can rack and pinion systems withstand variations in environmental conditions?

Rack and pinion systems are designed to operate reliably under various environmental conditions. Here’s a detailed explanation of how these systems can withstand variations in environmental conditions:

Rack and pinion systems are commonly used in a wide range of industries and applications, and they are engineered to withstand different environmental factors. Some key considerations regarding the ability of rack and pinion systems to withstand variations in environmental conditions include:

- Temperature: Rack and pinion systems are designed to operate effectively within a specified temperature range. The materials chosen for the components should be capable of withstanding both high and low temperatures without significant degradation. For example, steel or stainless steel components can handle a wider temperature range compared to certain plastics. In extreme temperature conditions, additional measures such as insulation or cooling systems may be required to ensure optimal performance.

- Humidity and Moisture: Rack and pinion systems can be designed to operate in environments with high humidity or moisture. Materials with good corrosion resistance, such as stainless steel or certain plastics, are often used to minimize the risk of rust or degradation due to moisture exposure. Proper sealing and protective coatings can also be applied to sensitive components to prevent water ingress and maintain system integrity.

- Dust and Particles: In environments where there is a presence of dust, dirt, or other particles, rack and pinion systems can be designed with protective measures. Sealed enclosures, gaskets, or covers can be employed to minimize the entry of contaminants into the system. Choosing materials with low friction properties can help reduce the accumulation of particles on the gear surfaces, ensuring smooth operation and minimizing wear.

- Chemical Exposure: Rack and pinion systems may encounter exposure to various chemicals depending on the application. In such cases, material selection is crucial to ensure compatibility with the specific chemical environment. Stainless steel or plastics that exhibit resistance to chemicals can be chosen to prevent corrosion or degradation. It’s important to consider the specific chemical composition, concentration, and duration of exposure when selecting materials.

- Vibration and Shock: Rack and pinion systems can be designed to withstand vibrations and shocks that may occur in certain applications. Robust construction, proper mounting, and securing mechanisms can help minimize the impact of vibrations and shocks on the system. Damping materials or isolation techniques may be employed to further reduce the transmission of vibrations and protect sensitive components.

- Outdoor and Harsh Environments: Rack and pinion systems used in outdoor or harsh environments may require additional protection. Enclosures, coatings, or specialized seals can be employed to shield the system from exposure to sunlight, rain, dust, or corrosive elements. Materials with enhanced UV resistance and weatherproof properties may be chosen to ensure long-term performance and durability.

By considering factors such as temperature, humidity, moisture, dust, chemicals, vibration, shock, and environmental exposure, rack and pinion systems can be designed to withstand variations in environmental conditions. Proper material selection, sealing mechanisms, protective coatings, and maintenance practices play crucial roles in ensuring the system’s reliability and longevity in diverse operating environments.

Can rack and pinion mechanisms be applied in CNC machining for positioning?

Yes, rack and pinion mechanisms can be successfully applied in CNC machining for precise positioning of machine tools and workpieces. Here’s a detailed explanation of how rack and pinion mechanisms can be utilized in CNC machining:

Rack and pinion mechanisms offer several advantages that make them suitable for positioning in CNC machining:

- Precision and Accuracy: Rack and pinion systems provide high precision and accuracy in positioning. The direct engagement between the pinion and the rack ensures a positive and backlash-free transfer of motion, allowing for precise movement and positioning of machine tools and workpieces. This characteristic is essential in CNC machining, where tight tolerances and accurate positioning are required.

- High Speed and Acceleration: Rack and pinion systems are capable of accommodating high-speed movements and rapid accelerations. The direct power transmission and efficient torque transfer of rack and pinion mechanisms enable quick and dynamic positioning, reducing idle times and improving overall machining efficiency. This characteristic is advantageous in CNC machining, where fast tool changes and rapid workpiece positioning are crucial for productivity.

- Load Handling Capability: Rack and pinion systems can handle significant loads while maintaining precise positioning. The engagement of the teeth provides a large contact area, allowing for the effective distribution of forces and torque. This capability is important in CNC machining, where heavy-duty cutting operations and the manipulation of large workpieces may be required.

- Compact Design: Rack and pinion systems offer a compact design, which is advantageous in CNC machining setups with limited space. The linear nature of the rack allows for efficient integration into the machine’s structure, minimizing the overall footprint. This compact design maximizes the workspace utilization and allows for flexible placement of the rack and pinion mechanism.

- Compatibility with CNC Control Systems: Rack and pinion systems can be easily integrated with CNC control systems. The position and motion of the rack and pinion mechanism can be precisely controlled and programmed using CNC software. This compatibility allows for seamless coordination between the rack and pinion system, servo motors, and other machine axes, enabling synchronized and coordinated movements for complex machining operations.

- Reliability and Durability: Rack and pinion systems are known for their durability and long service life. When properly designed and maintained, they can withstand the demands of CNC machining, including continuous operation, high speeds, and repetitive movements. This reliability is vital in CNC machining, where machine uptime and consistent performance are critical.

Overall, the application of rack and pinion mechanisms in CNC machining provides precise positioning, high-speed capability, load handling capabilities, compactness, compatibility with CNC control systems, and reliability. These characteristics make rack and pinion systems a popular choice for CNC machine tools, such as gantry mills, CNC routers, plasma cutters, and laser cutting machines.

In which industries are rack and pinion systems commonly used?

Rack and pinion systems are widely used in numerous industries due to their versatility, efficiency, and precise motion control. Here’s a detailed explanation of the industries where rack and pinion systems are commonly employed:

- Automotive Industry: Rack and pinion systems have extensive use in the automotive industry, particularly in steering mechanisms. They are commonly found in passenger cars, trucks, and other vehicles where they enable smooth and responsive steering control.

- Robotics and Automation: Rack and pinion systems play a vital role in robotics and automation. They are utilized in various robotic applications, including robotic arms, gantry systems, pick-and-place robots, and CNC machines. Rack and pinion systems provide accurate and controlled linear motion for precise positioning and manipulation in these industries.

- Industrial Machinery: Rack and pinion systems are commonly employed in industrial machinery and equipment. They are used in applications such as cutting machines, printing presses, packaging equipment, material handling systems, and more. The precise and efficient linear motion provided by rack and pinion systems enhances the performance and productivity of industrial machinery.

- Construction Industry: Rack and pinion systems are utilized in the construction industry for various applications. They are commonly found in construction equipment such as cranes, lifts, and scaffolding systems, where they enable controlled vertical movement and positioning.

- Medical Equipment: Rack and pinion systems are used in medical equipment for tasks that require precise linear motion control. They can be found in equipment such as medical imaging devices, surgical robots, patient positioning systems, and laboratory automation equipment.

- Aerospace and Defense: Rack and pinion systems are employed in the aerospace and defense industries for various applications. They are used in aircraft control mechanisms, satellite systems, missile guidance systems, and other aerospace and defense equipment that require accurate and reliable linear motion control.

- Entertainment Industry: Rack and pinion systems find applications in the entertainment industry, particularly in stage and theater setups. They are used for moving stage elements, lighting fixtures, and other equipment to create dynamic and precise movements during performances.

- Other Industries: Rack and pinion systems are also utilized in other industries, including agriculture, energy, manufacturing, and more. They find applications in equipment such as agricultural machinery, solar tracking systems, industrial automation, and specialized machinery.

Rack and pinion systems offer a versatile and efficient solution for converting rotational motion into linear motion, making them valuable in a wide range of industries that require precise motion control, reliability, and compact design.

editor by Dream 2024-05-16