Product Description

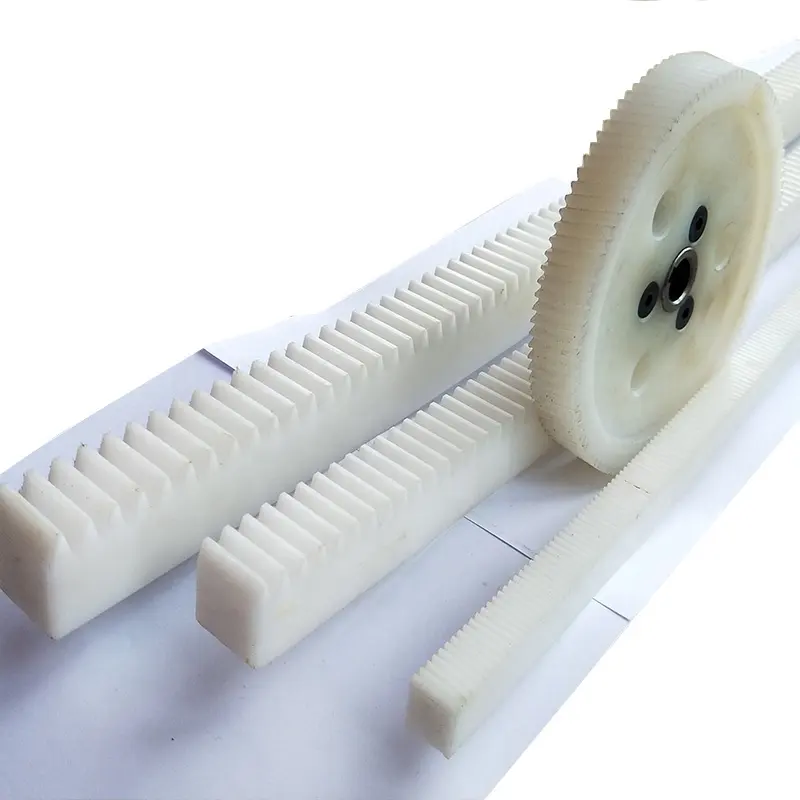

custom spur cnc plastic nylon pom flexible gear rack and pinion for linear motion

ZheJiang Enginnering Plastics Industries (Group) co., Ltd established in January 2009 , is a professional production

of “engineering plastics accessories” high-tech enterprises. Company main products : UHMW-PE , MC Nylon , PA6 ,

POM, HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic, PEEK, PPS , PTFE , PVDF , PAI, PEI , PSU , PI, PBI

Antistatic product series . Company also provide wide range of accessories processing conditions , such as mass

customization production ability , exquisitemanufacturing technology and advanced production equipment , professional

technical advice and after-sales service. Companies strictly enforce the ISO9001(2008) International quality certification

system , the product quality conforms to the EU Rohs standard .

| Name | Plastic nylon6 sleeve |

| Material | High Performance Engineering Plastics–100% Virgin Nylon6 Raw Material. |

| Color | Nature color / Customized |

| Advantage | 1.Very good sliding properties even without lubrication 2.Good thermal mechanical bearing strength 3.Good chemical and hydrolysis resistance even against superheated steam 4.Very wear resistant 5.Very rigid 6.Light weight |

| Brand Name | Engineering Plastics / OEM |

| Size | Custom made as your drawing or sample |

| Density | 1.2g/cm3 |

| Manufacture way | Molding Injection and CNC Machinery process |

| MOQ | Accept the Sample order, and supply good price for the big quantity order. |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Sample | Free the molding injection sample for customers after paying the mould Cost. |

| Sample time | 30 Days for manufacturing the injection mould and finished the samples for Customers. |

| Mass production time | 10-30 days based on the order quantity. |

| Payment | PayPal, Escrow, Western union, Money Gram, T/T and Alibaba Trade Assurance. |

| Packing | 5-ply environment-friendly corrugated boxes/ Plastic Pallets/ Wooden Pallets/ wooden cartons/ 20 feet Container / 40feet Container/ Customized |

| Other | 24 hours instant and comfortable customer service. Shipping status notification during delivery. Regular notification of new styles & hot selling styles |

1, thread H4 fine car grade tolerance 4H fine car grade production, vertical accuracy 0.005mm

2, high strength steel hardness HRC28, phosphoric acid plating on the surface and after lubrication

Each lock nut is provided with independent packaging to ensure qualitySpecializing in the production of “engineering plastic accessories” of high-tech enterprises, the company has a set of

imported production equipment and CNC processing equipment, processing means advanced, strong technical force.The company has rich experience, strong strength and participated in many high-end exhibitions;Many partners from

other countries are visitingQ1. We don’t have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,injection molding machine, extruder, moldin

machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and the highest

temperature is 300ºC. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square CHINAMFG and has 100 employees. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Size: | According to Drawing or Sample |

|---|---|

| Color: | Natural, White, Black, Green, Blue, Yellow |

| Deansity: | 1.2 |

| Shape: | Tube, Sheet ,Parts, Gear, Gear Rack, Pulley,etc |

| Brand: | Engineering Plastic |

| Application: | Food and Beverage Light Industry,Electronic Indust |

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with rack and pinion?

When working with rack and pinion systems, several safety considerations should be kept in mind to ensure the well-being of personnel and the proper functioning of the equipment. Here’s a detailed explanation of the safety considerations:

- Guarding: It is essential to install appropriate guarding around the rack and pinion system to prevent accidental contact with moving parts. Guards should be designed to restrict access to the gears, especially the pinion gear, to avoid the risk of entanglement or injury. Guards can be physical barriers, safety enclosures, or interlocked covers that prevent access to the moving components while allowing necessary maintenance and inspection activities.

- Emergency Stop: Incorporating an emergency stop system is crucial for safety. An easily accessible emergency stop button or switch should be installed to quickly halt the motion of the rack and pinion system in case of an emergency or when there is an imminent risk of injury. The emergency stop system should be clearly labeled, easily identifiable, and functionally tested to ensure its reliability.

- Lockout/Tagout Procedures: When performing maintenance, repair, or adjustment tasks on the rack and pinion system, proper lockout/tagout procedures should be followed. This involves isolating the system from its power source, locking and tagging the energy isolation devices, and ensuring that authorized personnel are aware of the ongoing work. Lockout/tagout procedures help prevent accidental start-up or energization of the system, safeguarding against potential injuries.

- Proper Training: Operators and maintenance personnel should receive adequate training on the safe operation, maintenance, and handling of rack and pinion systems. They should be familiar with the potential hazards associated with the equipment and understand the safety protocols and procedures to follow. Training should cover topics such as proper use of personal protective equipment (PPE), safe working distances, emergency response, and the recognition of abnormal operating conditions.

- Regular Inspections and Maintenance: Routine inspections and maintenance should be conducted to identify any potential safety hazards or signs of wear and tear. This includes inspecting the rack and pinion gears, checking for loose or damaged components, and ensuring proper lubrication. Any identified issues should be addressed promptly to maintain the safe operation of the system.

- Load Capacity and Overload: It is crucial to operate the rack and pinion system within its specified load capacity limits. Exceeding the load capacity can lead to gear failure or other mechanical issues, posing a safety risk. Care should be taken to properly assess and understand the weight and forces involved in the application and ensure that the rack and pinion system is appropriately sized and rated for the intended load.

- Environmental Factors: Consideration should be given to environmental factors that can affect the safe operation of the rack and pinion system. For example, moisture, dust, extreme temperatures, or corrosive substances can impact the performance and longevity of the system. Adequate environmental protection measures, such as sealing, ventilation, or specialized coatings, should be implemented as necessary to maintain safe and reliable operation.

By adhering to proper guarding, implementing emergency stop systems, following lockout/tagout procedures, providing training, conducting regular inspections, operating within load capacity limits, and considering environmental factors, the safety of working with rack and pinion systems can be effectively maintained. Prioritizing safety ensures a secure working environment and minimizes the risk of accidents or injuries.

How do rack and pinion systems handle variations in backlash and precision?

Rack and pinion systems are designed to minimize variations in backlash and ensure high precision in motion control. Here’s a detailed explanation of how rack and pinion systems handle variations in backlash and precision:

Backlash in Rack and Pinion Systems:

Backlash refers to the play or clearance between the teeth of the pinion and the rack in a rack and pinion system. It can result in a loss of precision and accuracy in motion control. However, there are several strategies employed to handle variations in backlash:

- Precision Manufacturing: Rack and pinion systems are manufactured with high precision to minimize backlash. The teeth of both the pinion and the rack are carefully machined to ensure accurate tooth profiles and proper tooth engagement. Precision manufacturing techniques, such as grinding and honing, are utilized to achieve tight tolerances and reduce backlash to a minimum.

- Preload Mechanisms: Preload mechanisms can be incorporated into rack and pinion systems to reduce or eliminate backlash. These mechanisms apply a slight force or tension to the pinion and the rack, ensuring constant contact between the teeth. By eliminating the clearance between the teeth, preload mechanisms minimize backlash and enhance precision. Common preload mechanisms include spring-loaded systems, adjustable shims, and anti-backlash devices.

- Compensation Techniques: Compensation techniques can be employed to handle variations in backlash. These techniques involve implementing controls or software algorithms that account for the expected backlash and compensate for it during motion control. By applying appropriate corrections and adjustments, the system can achieve the desired precision and accuracy, even in the presence of backlash.

Precision in Rack and Pinion Systems:

Precision in rack and pinion systems refers to the ability to achieve accurate and repeatable motion control. Several factors contribute to maintaining precision in rack and pinion systems:

- Rigidity and Structural Integrity: The rigidity and structural integrity of the rack and pinion system play a crucial role in maintaining precision. Stiffness in the system ensures minimal deflection or deformation during operation, allowing for accurate positioning and motion control. Proper selection of materials, adequate sizing of components, and robust construction are essential for maintaining precision.

- Lubrication and Maintenance: Proper lubrication is important for reducing friction and wear in rack and pinion systems. Adequate lubrication minimizes variations in friction, ensuring smooth and consistent motion. Regular maintenance, including lubrication checks and cleaning, helps to preserve precision over time and prevent degradation in performance.

- System Alignment: Precise alignment of the rack and pinion system is critical for maintaining precision. Proper alignment ensures accurate tooth engagement and minimizes variations in backlash. Alignment procedures may involve careful adjustment of mounting positions, gear meshing, and system calibration to achieve optimal precision.

By employing precision manufacturing techniques, incorporating preload mechanisms, utilizing compensation techniques, ensuring system rigidity, implementing effective lubrication and maintenance practices, and maintaining proper system alignment, rack and pinion systems can handle variations in backlash and maintain high precision in motion control. These measures contribute to accurate positioning, repeatability, and reliable performance in a wide range of applications.

What advantages do rack and pinion systems offer for precise motion control?

Rack and pinion systems offer several advantages for precise motion control. Here’s a detailed explanation of the advantages:

- Precision: Rack and pinion systems provide high precision in motion control. The teeth on the rack and pinion gears mesh closely, resulting in minimal backlash or play. This close engagement allows for accurate and repeatable linear motion, making rack and pinion systems suitable for applications that require precise positioning and movement control.

- Direct Mechanical Linkage: Rack and pinion systems offer a direct mechanical linkage between the rotating pinion gear and the linearly moving rack. This direct linkage ensures a one-to-one correspondence between the rotational motion of the pinion gear and the linear motion of the rack. The absence of intermediate linkages or mechanisms reduces the chances of mechanical play or lost motion, contributing to the overall precision of the system.

- Low Backlash: Backlash refers to the amount of clearance or play between mating teeth in a gear system. Rack and pinion systems can be designed to have low backlash, which is crucial for precise motion control. The minimal backlash in rack and pinion systems allows for accurate and immediate response to changes in input, ensuring precise positioning and minimizing errors in motion control applications.

- High Repeatability: Rack and pinion systems offer high repeatability in motion control. Once the gear teeth are engaged, the linear motion of the rack follows the rotational motion of the pinion gear consistently. This repeatability allows for precise and consistent positioning of the rack, making rack and pinion systems suitable for tasks that require repeated and accurate movements.

- Efficient Power Transmission: Rack and pinion systems provide efficient power transmission from the rotating pinion gear to the linearly moving rack. The direct mechanical linkage and the close meshing of teeth minimize energy losses, ensuring that a significant portion of the input power is efficiently converted into linear motion. This efficiency is beneficial in applications where energy conservation is important.

- Fast Response: Rack and pinion systems offer fast response in motion control. The teeth on the rack and pinion gears allow for rapid acceleration and deceleration, enabling quick and responsive movements. This fast response time is valuable in applications that require dynamic motion control or rapid changes in position.

- Compact Design: Rack and pinion systems have a compact design, which is advantageous in applications with limited space. The linear nature of the rack allows for efficient packaging, making rack and pinion systems suitable for compact machinery and equipment.

Overall, rack and pinion systems provide high precision, low backlash, efficient power transmission, and fast response, making them well-suited for applications that require precise motion control. These advantages make rack and pinion systems popular in industries such as automotive, robotics, machinery, automation, and more.

editor by CX 2024-04-09