Product Description

Product Description

Certificate

Features

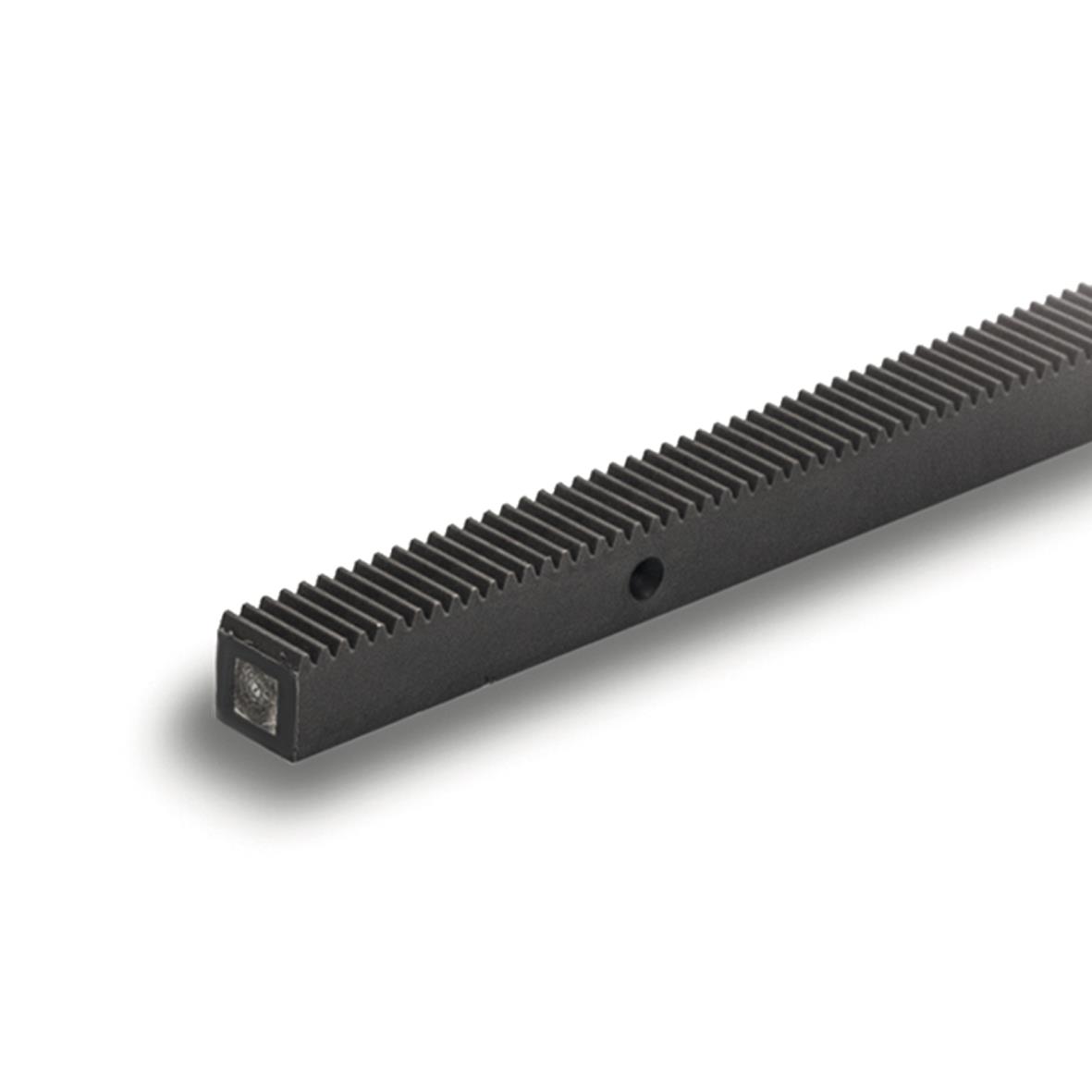

1. Available in sizes in Module1.5/2/3/4/5/6/7/8/9/10

2. Repeatability of up to ± 0.01mm

3. Powerful rack and pinion drives for reliable movements.

4. Extremely compact frame with high inherent stiffness

5. It is designed for high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Improve accuracy, Easy assemble, etc.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CHINAMFG the rack and pinion.

| Brand | TOCO |

| Model | Rack and pinion |

| Size customize | Module1.5/2/3/4/5/6/7/8/9/10 |

| HS-CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 15 business days for sample, 35 days for the bulk |

| Keyword | Rack and pinion |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Catalogs

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

CHINAMFG Group is a professional manufacturer of transmission components in China, mastering key technologies and focusing on innovative research and design. CHINAMFG Group has multiple product design patents and through the ISO9001 certification and national high-tech enterprise certification.

CHINAMFG has a complete product line, including Mono Stage, Linear Module, Linear Xihu (West Lake) Dis., Ball Screw, Support Unit, Rack and Pinion.

You may find more information on our website at www.toco.tw.

Any questions, pls feel free to contact us.

We mainly produce Mono Stage, Linear Module, Linear Xihu (West Lake) Dis., Ball Screw, Support Unit, Rack and Pinion.

FAQ :

1. Service :

a. Help customers to choose the correct model, with CAD & PDF drawing for your reference.

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.T/T, Paypal, Western Union is

acceptable.

3.Delivery :

sample: 5-10 business days after payment confirmed.

Bulk order:10-20 workdays after deposit received.

4. Guarantee Time

TOCO provides a one-year quality guarantee for the products from your purchase date, except for

the artificial damage.

5.After sale-Service

During the warranty period, any quality problem of the CHINAMFG product, once confirmed, we will

send a new 1 to replace.

| Application: | Machinery, CNC Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Straight/Helical |

| Material: | Stainless Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do rack and pinion systems handle variations in load capacity and speed?

Rack and pinion systems are designed to handle variations in load capacity and speed effectively. Here’s a detailed explanation of how they handle these variations:

- Load Capacity: Rack and pinion systems can be designed to accommodate a wide range of load capacities. The load capacity primarily depends on the strength and size of the rack and pinion components, such as the rack material, tooth size, and pinion gear dimensions. By selecting appropriate materials and dimensions, rack and pinion systems can be optimized to handle varying load capacities. For higher load requirements, heavier-duty materials and larger gear sizes can be used to ensure sufficient strength and durability.

- Speed: Rack and pinion systems can also handle variations in speed. The speed of the system is influenced by factors such as the rotational speed of the pinion gear and the pitch of the rack. By adjusting these parameters, the speed of the system can be optimized to suit specific application requirements. For high-speed applications, rack and pinion systems can be designed with smaller pitch and lighter components to minimize inertia and allow for rapid acceleration and deceleration. On the other hand, for slower-speed applications, larger pitch and heavier components can be used to enhance stability and load-carrying capacity.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of rack and pinion systems. Lubricants help reduce friction and wear between the rack and pinion gears, ensuring efficient power transmission and minimizing the risk of damage. The type and frequency of lubrication required may vary depending on the load capacity and speed of the system. Regular maintenance, including inspection and lubrication, is important to ensure optimal performance and longevity of the rack and pinion system under varying load and speed conditions.

- Design Considerations: When designing rack and pinion systems, it is essential to consider the anticipated load capacity and speed requirements. Factors such as gear material selection, tooth profile, gear module, and tooth width play a significant role in determining the system’s ability to handle variations in load and speed. The design should take into account the maximum expected load and speed to ensure that the rack and pinion components are appropriately sized and capable of withstanding the anticipated conditions.

- System Feedback and Control: In applications where load and speed variations are significant, incorporating system feedback and control mechanisms can enhance the performance of rack and pinion systems. Sensors and feedback devices can be used to monitor the load and speed, allowing for real-time adjustments and control. This feedback information can be utilized to implement closed-loop control systems that adjust the motor torque or speed to maintain precise motion control under varying load conditions.

By considering factors such as load capacity, speed, lubrication, maintenance, and design considerations, rack and pinion systems can effectively handle variations in load and speed, ensuring reliable and precise motion control in a wide range of applications.

Can rack and pinion mechanisms be used for both rotary and linear motion?

Yes, rack and pinion mechanisms can be utilized to convert rotary motion into linear motion or vice versa. Here’s a detailed explanation of how rack and pinion mechanisms can be employed for both rotary and linear motion:

Rack and pinion systems consist of a gear called the pinion and a linear gear called the rack. The pinion is a small gear with teeth that mesh with the teeth of the rack, which is a straight, flat, or cylindrical bar with teeth along its length. Depending on the arrangement and application, rack and pinion mechanisms can serve two fundamental purposes:

- Rotary-to-Linear Motion: In this configuration, the rotary motion of the pinion gear is converted into linear motion along the rack. As the pinion rotates, its teeth engage with the teeth of the rack, causing the rack to move in a linear direction. By controlling the rotational motion of the pinion, the position, speed, and direction of the linear motion can be precisely controlled. This mechanism is commonly used in applications such as CNC machines, robotics, linear actuators, and steering systems in vehicles.

- Linear-to-Rotary Motion: In this configuration, the linear motion of the rack is converted into rotary motion of the pinion. As the rack moves linearly, it causes the pinion gear to rotate. This conversion of linear motion to rotary motion can be used to drive other components or systems. For example, a linear motion generated by an actuator can be transformed into rotational motion to drive a rotary mechanism or a rotary tool. This configuration is often employed in applications such as power steering systems, elevators, and machinery where linear input needs to be translated into rotary output.

Rack and pinion mechanisms offer several advantages for converting between rotary and linear motion. They provide a simple and efficient means of transmitting motion and force. The engagement of the teeth between the pinion and the rack ensures a positive and precise transfer of motion, resulting in accurate positioning and smooth operation. Additionally, rack and pinion systems can achieve high speeds and transmit substantial amounts of torque, making them suitable for a wide range of industrial applications.

It’s important to note that the design and implementation of rack and pinion systems for rotary-to-linear or linear-to-rotary motion require careful consideration of factors such as gear ratios, backlash, precision, load capacity, lubrication, and system alignment. Proper selection of materials, tooth profiles, and maintenance practices ensures optimal performance and longevity of the rack and pinion mechanism in various applications.

How does a rack and pinion compare to other mechanisms for linear motion?

When comparing a rack and pinion mechanism to other mechanisms for linear motion, several factors come into play. Here’s a detailed comparison:

- Simplicity: Rack and pinion systems are relatively simple in design, consisting of just two main components: a rack and a pinion gear. This simplicity makes them easier to manufacture, assemble, and maintain compared to more complex linear motion mechanisms.

- Precision: Rack and pinion systems offer high precision in linear motion control. The teeth on the rack and pinion gears mesh closely, minimizing backlash and allowing for accurate and repeatable motion. This precision is crucial in applications that require precise positioning and movement control.

- Efficiency: Rack and pinion systems are known for their efficiency in power transmission. The direct mechanical linkage between the rotating pinion gear and the linearly moving rack minimizes energy loss, resulting in efficient conversion of rotational motion to linear motion. This efficiency is particularly advantageous in applications where energy conservation is important.

- Load Capacity: Rack and pinion systems can handle a wide range of load capacities, depending on the design and materials used. The teeth on the rack and pinion gears distribute the load evenly, allowing for efficient transmission of force. However, in certain high-load applications, alternative mechanisms like linear actuators or ball screw systems may offer higher load-bearing capabilities.

- Speed: Rack and pinion systems can achieve high speeds in linear motion applications. The direct engagement between the teeth on the rack and pinion allows for rapid acceleration and deceleration, making them suitable for applications that require quick and responsive movements.

- Size and Space Requirements: Rack and pinion systems have a compact design, which is advantageous in applications where space is limited. The linear nature of the rack allows for efficient packaging, making them suitable for compact machinery and equipment.

- Cost: Rack and pinion systems are generally cost-effective compared to some alternative linear motion mechanisms. Their simple design and ease of manufacturing contribute to lower production costs, making them a cost-efficient choice in many applications.

In summary, rack and pinion systems offer simplicity, precision, efficiency, and high-speed capabilities in linear motion applications. While they may have certain limitations in terms of load capacity compared to other mechanisms, their overall advantages make them a popular choice in various industries, including automotive, robotics, machinery, and automation.

editor by CX 2023-10-23