Product Description

New Power Steering Rack Gear Pinion Caja Cremallera Direccion for CZPT Hilux Vigo 1kd Y 2kd 442-1

| After-sales Service: | Available |

|---|---|

| Warranty: | 12 Months |

| Type: | Steering Rack |

| Material: | Aluminum/Alloy |

| Certification: | ISO |

| Automatic: | Manual |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can rack and pinion mechanisms be customized for specific machinery and equipment?

Yes, rack and pinion mechanisms can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation of how rack and pinion systems can be customized:

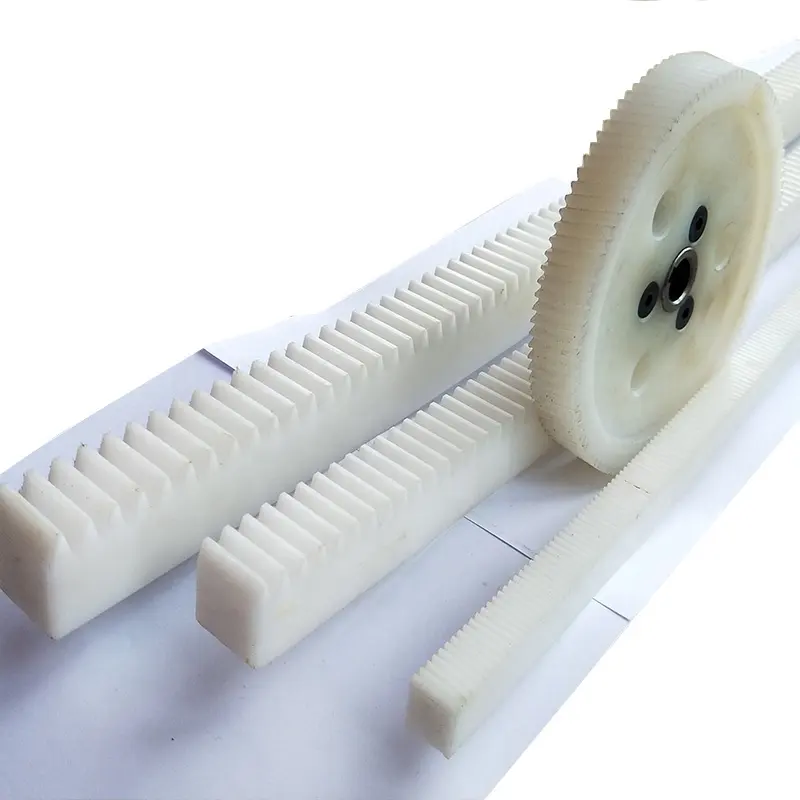

- Size and Dimensions: Rack and pinion systems can be customized in terms of their size and dimensions to fit the available space and integration requirements of the machinery or equipment. The length, width, and height of the rack can be adjusted, and the pinion gear size can be modified to ensure proper fit and compatibility.

- Materials: The choice of materials for the rack and pinion components can be customized based on factors such as load capacity, environmental conditions, and specific application requirements. Different materials, such as steel, stainless steel, aluminum, or various alloys, can be selected to optimize strength, durability, corrosion resistance, and other desired properties.

- Teeth Profile: The tooth profile of the rack and pinion gears can be customized to meet specific application needs. Different tooth profiles, such as straight, helical, or even custom-designed profiles, can be utilized to enhance load distribution, reduce noise, increase contact area, or improve efficiency based on the unique requirements of the machinery or equipment.

- Precision and Tolerance: The precision and tolerance levels of rack and pinion systems can be customized to achieve the desired level of accuracy and motion control. Tighter tolerances can be specified to enhance positioning and repeatability, while looser tolerances may be suitable for applications that prioritize cost-effectiveness over extreme precision.

- Mounting Options: Rack and pinion systems can be customized to offer various mounting options to facilitate integration with specific machinery or equipment. Mounting holes, brackets, or specific attachment mechanisms can be incorporated into the design to ensure proper alignment, stability, and ease of installation.

- Accessories and Features: Customized rack and pinion systems can include additional accessories or features to enhance functionality and application-specific requirements. This can include the incorporation of sensors, limit switches, lubrication systems, protective covers, or any other components that are necessary for the proper operation and maintenance of the machinery or equipment.

- Integration with Control Systems: Rack and pinion systems can be customized to integrate seamlessly with the control systems of the machinery or equipment. This allows for synchronization, feedback control, and coordination with other system components, enabling precise motion control and automation in line with specific application needs.

By considering factors such as size, dimensions, materials, tooth profile, precision, mounting options, accessories, and integration with control systems, rack and pinion mechanisms can be effectively customized to meet the unique requirements of different machinery and equipment. Customization ensures optimal performance, reliability, and compatibility, allowing rack and pinion systems to be tailored for specific applications across various industries.

Can rack and pinion mechanisms be used for both rotary and linear motion?

Yes, rack and pinion mechanisms can be utilized to convert rotary motion into linear motion or vice versa. Here’s a detailed explanation of how rack and pinion mechanisms can be employed for both rotary and linear motion:

Rack and pinion systems consist of a gear called the pinion and a linear gear called the rack. The pinion is a small gear with teeth that mesh with the teeth of the rack, which is a straight, flat, or cylindrical bar with teeth along its length. Depending on the arrangement and application, rack and pinion mechanisms can serve two fundamental purposes:

- Rotary-to-Linear Motion: In this configuration, the rotary motion of the pinion gear is converted into linear motion along the rack. As the pinion rotates, its teeth engage with the teeth of the rack, causing the rack to move in a linear direction. By controlling the rotational motion of the pinion, the position, speed, and direction of the linear motion can be precisely controlled. This mechanism is commonly used in applications such as CNC machines, robotics, linear actuators, and steering systems in vehicles.

- Linear-to-Rotary Motion: In this configuration, the linear motion of the rack is converted into rotary motion of the pinion. As the rack moves linearly, it causes the pinion gear to rotate. This conversion of linear motion to rotary motion can be used to drive other components or systems. For example, a linear motion generated by an actuator can be transformed into rotational motion to drive a rotary mechanism or a rotary tool. This configuration is often employed in applications such as power steering systems, elevators, and machinery where linear input needs to be translated into rotary output.

Rack and pinion mechanisms offer several advantages for converting between rotary and linear motion. They provide a simple and efficient means of transmitting motion and force. The engagement of the teeth between the pinion and the rack ensures a positive and precise transfer of motion, resulting in accurate positioning and smooth operation. Additionally, rack and pinion systems can achieve high speeds and transmit substantial amounts of torque, making them suitable for a wide range of industrial applications.

It’s important to note that the design and implementation of rack and pinion systems for rotary-to-linear or linear-to-rotary motion require careful consideration of factors such as gear ratios, backlash, precision, load capacity, lubrication, and system alignment. Proper selection of materials, tooth profiles, and maintenance practices ensures optimal performance and longevity of the rack and pinion mechanism in various applications.

In which industries are rack and pinion systems commonly used?

Rack and pinion systems are widely used in numerous industries due to their versatility, efficiency, and precise motion control. Here’s a detailed explanation of the industries where rack and pinion systems are commonly employed:

- Automotive Industry: Rack and pinion systems have extensive use in the automotive industry, particularly in steering mechanisms. They are commonly found in passenger cars, trucks, and other vehicles where they enable smooth and responsive steering control.

- Robotics and Automation: Rack and pinion systems play a vital role in robotics and automation. They are utilized in various robotic applications, including robotic arms, gantry systems, pick-and-place robots, and CNC machines. Rack and pinion systems provide accurate and controlled linear motion for precise positioning and manipulation in these industries.

- Industrial Machinery: Rack and pinion systems are commonly employed in industrial machinery and equipment. They are used in applications such as cutting machines, printing presses, packaging equipment, material handling systems, and more. The precise and efficient linear motion provided by rack and pinion systems enhances the performance and productivity of industrial machinery.

- Construction Industry: Rack and pinion systems are utilized in the construction industry for various applications. They are commonly found in construction equipment such as cranes, lifts, and scaffolding systems, where they enable controlled vertical movement and positioning.

- Medical Equipment: Rack and pinion systems are used in medical equipment for tasks that require precise linear motion control. They can be found in equipment such as medical imaging devices, surgical robots, patient positioning systems, and laboratory automation equipment.

- Aerospace and Defense: Rack and pinion systems are employed in the aerospace and defense industries for various applications. They are used in aircraft control mechanisms, satellite systems, missile guidance systems, and other aerospace and defense equipment that require accurate and reliable linear motion control.

- Entertainment Industry: Rack and pinion systems find applications in the entertainment industry, particularly in stage and theater setups. They are used for moving stage elements, lighting fixtures, and other equipment to create dynamic and precise movements during performances.

- Other Industries: Rack and pinion systems are also utilized in other industries, including agriculture, energy, manufacturing, and more. They find applications in equipment such as agricultural machinery, solar tracking systems, industrial automation, and specialized machinery.

Rack and pinion systems offer a versatile and efficient solution for converting rotational motion into linear motion, making them valuable in a wide range of industries that require precise motion control, reliability, and compact design.

editor by CX 2023-09-08